Customer Interview with Bailey Trailers – “Making it better for the next generation”.

Bailey is the leading brand of agricultural trailers in the UK and were established back in 1982, in Lincolnshire. Witham Group are proud to supply all the paints and lubricants for their trailers, including bulk hydraulic oil, sealant, greases, hand cleaners and degreasers.

Here, Managing Director, Michael Bailey shares his thoughts with us on over 40 years of the family business, the UK agricultural market and why he believes that Bailey is well positioned for the economic storm that lies ahead…

What is the History of your Business?

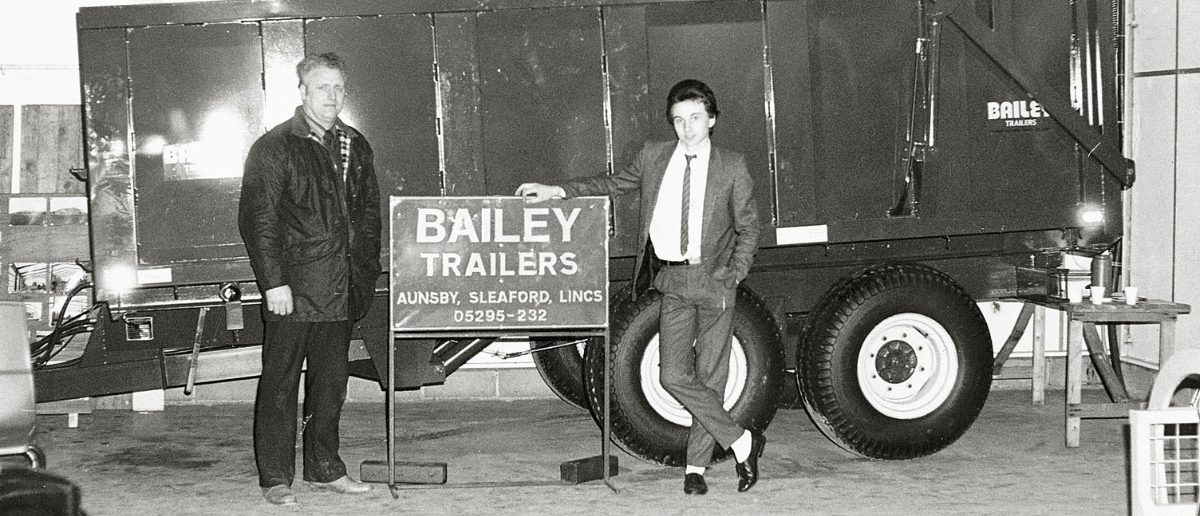

My dad, Tom Bailey started Bailey back in 1982. First and foremost we are engineers, driven by our founding principles of innovation and quality. However, farming is in our DNA too because our family once farmed in Lincolnshire.

The original design ideas came from my dad, who saw the potential for utilising his expertise to build a better trailer for local farmers in Lincolnshire. Being a welder, he knew they needed good equipment which lasts. We wanted to create a trailer like a sealed unit, with no leaks and with strong welded panels that would suit their needs. Being engineers, we were able to design and make the first trailer to a specific robust standard that had not been seen before.

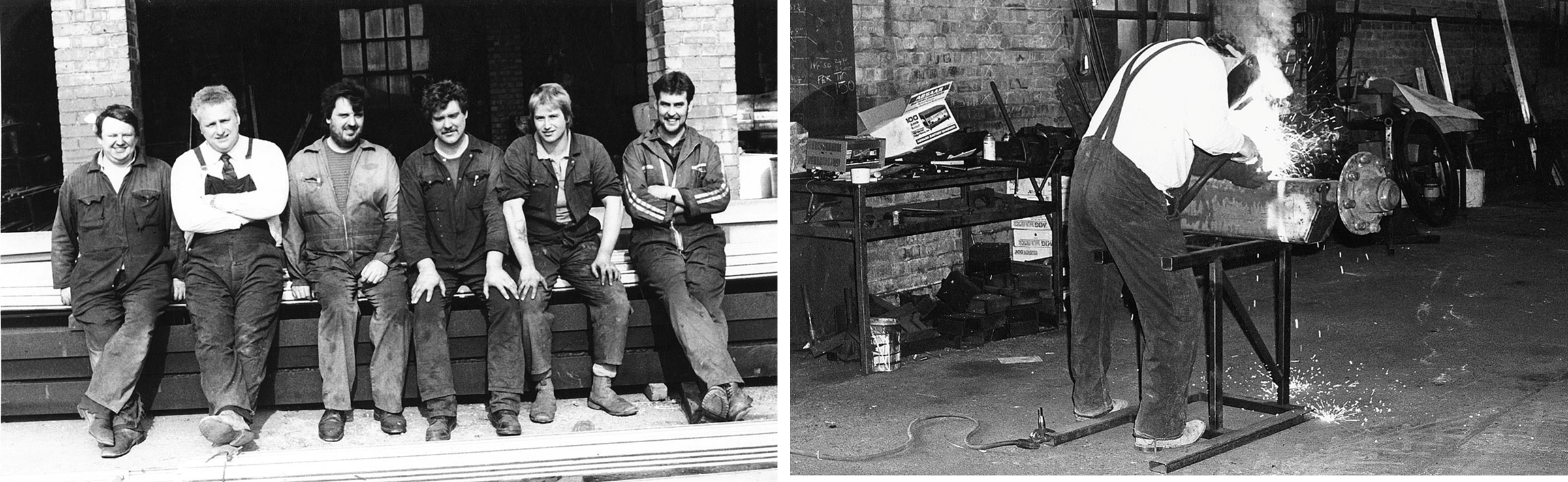

We made the first TB trailer for a local customer on the Harrowby Hall estate, which soon caught the attention of the local farming community. It wasn’t long before orders were coming in thick and fast and we turned our attention to designing the Bale Trailer that farmers had been asking for. In 1983, we opened the first Bailey dealership with Sharmans Agriculture in Melton Mowbray. We started with just 3 staff, and in 1988, we introduced the Contract Dumper and two years later, launched the High Lift trailer. By the early 1990’s, we had outgrown our space, so we purchased a workshop site in Aunsby and moved production to a larger shed which allowed us to expand the factory, increase output and develop more product lines, including our Flat Deck, Low Loader and Fuel Bowser.

We kept listening to what customers needed in the field and continued to make the best products we could. In 1998, we developed our Beeteaper trailer range, which is designed especially for transporting and heaping beet and features a unique tipping angle of approximately 60°. Sugar beet was in big demand at this time, so this new trailer design seemed to hit the mark.

Our trailers were growing in popularity, and we needed an identity so they could be more instantly relatable to our Bailey brand. In 2002, we introduced the famous green and silver Bailey Trailer colours across all our products and company image. This helped us become more recognised and our products identified back to our family brand.

Over the next decade, we invested in laser cutting technology for the factory and installed a machine shop. We started making products for the construction and utilities sectors as well as agriculture, launching the Contract Tipper, which is the perfect solution for hauling either topsoil or stone but also has a versatile sides option to still be able to transport grain.

In 2007, we proudly celebrated our 25 year anniversary, and with growing demand, 3 years later, moved from our small village site to a new purpose built 70,000 sq.ft factory in Sleaford. We also introduced commercial braking systems onto our larger trailers, which made a massive difference to their drive-ability and safety. In 2015, we opened a special fitting and finishing facility at the factory, which helped streamline production and enable us to make more trailers, more efficiently.

Since that time, we have continued to invest in the business, we have used technology to help us grow, installing new robotic welders and other automated design systems to improve our capabilities. Perhaps this is why we have always believed that in order for farmers to rely on equipment, it must be made using the most advanced technology, components and processes, complimented by meticulous design and rigorous testing.

Today, the very first trailer sits proudly outside our reception and sometimes we take it to a local customer, and it helps out with harvest. It’s still going strong. Just the other day, I took a load of corn in with it, and I thought how ever did farmers sit in a tractor pulling a ten tonne trailer with no sprung draw-bar or fancy suspension! In its day it was a real game-changer, but things have moved on leaps and bounds.

Congratulations on 40 years of Bailey Trailers this year!

How does this make you feel?

I feel proud to be part of it. If you asked my father when the first trailer rolled off the production line 40 years ago if he could have envisaged where we are today, he wouldn’t have thought it possible. We’ve come a long way, we’re still a family firm, there’s a next generation working here and that’s how we want it to be.

What sets Bailey apart from other trailer manufacturers?

I would like to think it’s the quality of the product that still lasts today, we try to stay at the top of the market The back-up we provide, we’re always there for our customers and dealers. We listen to people and keep looking for new ideas, new technology to our products, whilst keeping the price as competitive as possible to help farmers. Our range of products has something for everyone, from agricultural trailers to machinery for construction and fuel bowsers. We know the conditions, muck, produce and aggregate that need shifting and our designs reflect all that’s needed with the help of ideas and feedback from our users.

We provide 24 hours support if needed and we are always there to help a customer or dealer in need.

What Gets You Out of Bed Every Morning?

I want to make the business better for the next generation. I have been here over 30 years now and there are 11 members of the Bailey family working together in the business, some of them 3rd generation. We are a strong team, all focussed on improving everything all the time and driving the business forward.

We are proud of where we are today. Our story is one of innovation, ambition and sheer hard work. In just 40 years we have grown from one man in a workshop into a major global brand producing in excess of a thousand trailers per year. Our products are sold and supported by a network of over 100 UK dealers as well as dealerships across Europe, Scandinavia and New Zealand.

We believe a lot in core values, family values. Those same values that drove our business when we started still drive us today and in a world of mergers and mass production, I think it’s very important to stay true to your roots. To offer something different but always try and be the best. The reason why people buy Bailey trailers is because they are the best and we want to keep it that way.

If You Could Do It All Again, What Would You Do Differently?

Buy more land when we bought the new factory, as we are running out of space again!

What are your biggest challenges?

The biggest challenge we face at this factory is labour. We’re finding it increasingly difficult to find people. For example, welders, go back a couple of years and if we whispered we’d got a vacancy there’d be a queue, now if you shout you’re lucky to find someone.

People don’t want to work like they used to, everybody wants more money but they don’t want to put the hours in. We’re not unique, you see it on TV every day and I talk to other business owners and hear the same stories. It’s easy to hide behind Brexit and COVID, but I think there’s more to it than that, I’m not sure what though. On the flip side we’re lucky that we have a number of good people here, we’d just like to add to their numbers and take the pressure off.

The volatility of price and availability of raw materials has been a challenge of late, there have been times we have struggled to source one or two components. The knock-on effect is a delay in production, which has added two to three weeks on occasion. If you know in advance you can plan for these issues and work around them, it’s when you receive a call half an hour before a delivery is expected telling you it’s not coming for three weeks that causes unnecessary problems.

What are your thoughts on the UK market over the next 12 months?

Within agriculture I think it will remain quite buoyant. The yields, particularly in Lincolnshire from what I’ve heard, have been much better than expected this year, the price per ton is healthy. Farmers have had a relatively low input harvest season because it’s been so dry, they should have seen some decent savings.

The UK economy is going into a period of recession. We’ve seen recessions before and we’ve come through them. There’s a lot of things people can manage without, but they still have to eat

What are your plans for the future?

In the short term at Bailey, we plan to sit tight, do what we do well, keep our heads down and carry on supporting farmers and our other sectors as we have always done. Our business model is sound, we’ve invested a lot of money in our plant over the last ten to twelve years and we have planning in to expand the factory and increase the business further in the near future. Luckily, the order book is looking healthy well into next year, we’ll carry on doing what we do best and see where it takes us.

How and why did you start using Witham Group?

I have known Dave Lagden from Witham for over 30 years, playing football with him as a young lad. He used to be called Dave “The Cat” Lagden as he was a good goalie in the football team that we both played for in Oasby. We already had a paint supplier which we were having problems with and I would see Dave at the agricultural shows and he kept on at me saying Witham should come and help sort his paint problems out and supply us. So, when the time was right, we invited Dave to Bailey Trailers, which would be about 4 years ago now, and after rigorous testing and paint trials over a period of 18 months, we were very happy to have Witham supply all the paint for our trailers. The paint is delivered in 200 litre barrels. The Bailey factory paints around 6 trailers a day using 125 litres of Woco Epoxy Primer paint and 125 litres of Woco Urethan Top Coat per day. We also now have Witham supply all the lubricants for our trailers, including bulk hydraulic oil, sealant, greases, hand cleaners and degreasers.

Dave and the Witham team bend over backwards to help ensure we have good paint, delivered on time and if we have any problems, it gets sorted quickly. We like using a local based business where we know who we are dealing with and they care about what they do.

Dave and the support team at Witham pull out all the stops and we have never had a problem.

Leave a Reply