Brake Fluids: Why are they so important on and off the track?

As critical as the engine is, one thing all motorists need to be able to rely on is their brakes, and a large part of this comes down to brake fluids.

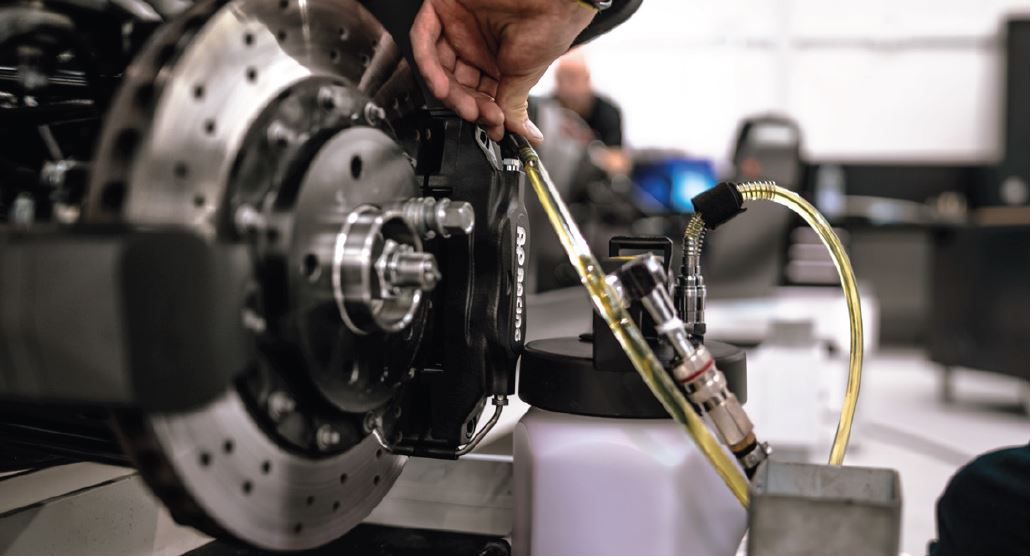

These non-compressible fluids transfer the movement of the brake pedal to the vehicle’s brake pads and discs, but not just any will do. Brake systems require high-quality fluids so drivers can enjoy powerful, lightning-fast brake response across lengthy drainage intervals. On a race track your brakes have to work much harder than on the road and high performance racing carbon and ceramic brakes produce extreme brake temperatures and work under extreme conditions of operation.

When a braking system gets too hot, brakes performance can fade even after just a couple of laps and can often result in an unfortunate premature end to the race. The majority of people understandably assume it’s the brake pads that are at fault, but more often than not, it’s actually the brake fluid.

How Does Brake Fluid Work?

Your braking system is filled with a hydraulic brake fluid. When you press the brake pedal it forces the fluid into the master cylinder and then down rubber or metal pipes to the brake callipers or wheel cylinders to actuate the brakes. Fluid is used to transfer the force from the pedal to the calliper because it cannot be compressed so gives a solid and consistent pedal feel. Additives such as corrosion inhibitors and antioxidants are used in brake fluids by the manufacturer to prolong the life of the products and prevent contamination.

What Affects Brakes Performance?

There are several different types of brake fluid, but they are grouped under two headings: those that are glycol based and those that are based on silicone. Most brake fluids are traditional glycol-ether based and these are hygroscopic. This means it absorbs water, which can result in internal corrosion of any steel components inside the braking system. This water not only causes corrosion, it adversely affects braking performance, as over time the water absorption reduces brake fluid’s effectiveness by lowering its boiling point. If the temperature of the brake fluid rises above 100°C (the boiling point of water). The water inside the brake fluid boils and the water turns into steam which is a gas. The gas can then be compressed which it shouldn’t ordinarily and so causes a spongy brake pedal, or worse no braking pressure at all which can lead to failure.

What’s The Difference Between DOT3, DOT4, DOT5 and DOT5.1 Brake Fluid?

The American Department of Transport (DOT) has devised a number of ratings for brake fluid. With all DOT3, DOT4 and DOT 5.1 brake fluids you’ll see a dry boiling point and a wet boiling point listed in their specs, which are based on their dry (fresh out of the bottle) and wet (after exposure to air and moisture) boiling points, A brake fluid must be categorised into one of the DOT classifications. The glycol-based brake fluids include DOT3, DOT4, Super DOT4 and DOT5.1. DOT5 is a silicon-based brake fluid.

Most cars use DOT4, but always check your handbook for guidance. With road cars at least, brake fluid is probably the single most neglected component within the braking system as most people do not check or regularly replace it.

What About Racing Brake Fluids?

Racing brake fluids are almost always more refined than standard brake fluids to engineer higher dry and wet boiling points. There are a huge variety of brake fluids out there in the marketplace and the costs vary enormously. When it comes to track days and Motorsport as vehicle weights and performance increase, so does the need for higher performing brake fluid. A good compromise between cost and performance is the Motul RBF660, with the best mid range performance being provided by Motul RBF600. For ultimate performance Motul’s RBF 700 High Performance Racing Brake Fluid has the highest dry

boiling point on the market (of products meeting DOT 4 standard) at 336C. The product offers highly consistent and maximum braking performance even under the most severe condition on road, race and rally. The product responds to the DOT 4 allowing this performance product to be used for road application as well.

How Often Should Brake Fluids Be Changed?

The lifespan of glycol-ether based brake fluid is generally around two years before most manufacturers recommend it should be renewed. According to the Government’s MOT inspection guidelines, MOT’s on cars only need to check the fluid level and a visual check for contamination. So, the bottom line is getting the right product for your type of vehicle is essential and ensure it’s a quality product, that complies to all the necessary standards to avoid unnecessary failures and maximum performance.

We would always recommend Brake Fluid is changed in line with the manufacturer recommendation. Finally, remember for all standard cars, it is critical to change brake fluid and not forget about it to keep safe on the road, never mind the track. Motul’s range of brake fluids are manufactured to exceed vehicle manufacturer’s standards, prevent corrosion of the metallic brake components and reduce oxidisation. The range has been designed for all modern brake

systems and a wide variety of vehicles for both normal road use and for racing conditions and use at high temperatures.

We look at the range that provides maximum braking power whatever the conditions.

To see and shop our range of brake fluids, visit our website here.

Leave a Reply