Grease is the word! We explain the different types of grease

We often get asked what the different types of grease are and how do you know which grease to use? Here we explain more…

WHERE DOES GREASE COME FROM?

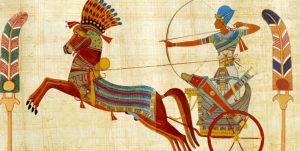

The word “grease” originates from the Latin word “Crassus” meaning fat and is the earliest known examples of lubrication when simple animal fats were used to lubricate the axles of chariot wheels by the ancient Egyptians more than 3,500 years ago.

Right up until the industrial revolution, machinery and mechanisms were still being lubricated by vegetable oils and animal fats, but then, in the early 19th Century, rapid developments in engineering, developed a need for more sophisticated lubricants, including making use of the newly discovered petroleum and its associated products and so the first modern greases were born.

WHAT IS GREASE?

Grease is a semi-solid lubricant that is produced using three main ingredients from a base oil with extra additives and thickeners to give it the properties it requires. Grease is an essential component of all aspects of engineering due to its defining property that when placed under pressure (shear), it behaves in a way that has approximately the same viscosity as the base oil used in the product, so providing and mimicking the lubricating qualities. The addition of the thickener is what differentiates a lubricating oil from a lubricating grease. The thickening agent is useful as it forms a thick layer between moving parts, preventing wear.

The first greases consisted of a heavy mineral oil fluid thickened with simple soaps. By dissolving or forming the calcium soap in the oil at temperatures above the melting point of the soap and then cooling it gradually, the dispersed soap solidified in the form of a fibrous structure, which retained the oil in a cohesive mass, in a similar way that a sponge retains water.

These early greases, whilst having good lubrication and water resistant properties, suffered from a very limited temperature range, and could not be used at temperatures above 60°C. Later the calcium soaps were replaced by sodium soaps which could operate at much higher temperatures but the disadvantage of being easily emulsified by water.

It was not until the mid-1940’s, that the most common grease of today, lithium grease was developed which could withstand temperatures of up to 120°C and excellent water repellent properties.

Lubricating Greases are used the world over in bearings, gears, and heavy-duty machinery. Greases are ideal when you need to only lubricate infrequently, or just the once. It is always preferable to use a lubricating oil as it is easier to handle, flows directly to the part needing lubrication and conducts heat away from the moving parts. This is why oil makes up around 95% of the total lubricants market. However, the use of oil necessitates the use of an associated reservoir, sometimes with a pump and piping system which is not always practical such as in the wheel bearings of vehicles. In these cases, greases are preferred and can be sealed into the bearing without the need of re-lubrication.

LITHIUM V CALCIUM GREASE… A NEW SUSTAINABLE OPTION?

For the past 60 years multi-purpose greases, based on lithium technology have made up more than 70% of the worlds lubricating grease. However, in recent years the demand for the mining of lithium continues to expand at an exponential rate as car manufacturers are being targeted to reduce CO2 emissions, by using battery operated vehicles, and the consequence of this is that lithium prices have reached an all-time high and the raw material itself is becoming a scarce commodity.

As a result of this a new wave of anhydrous Calcium based greases (contains no water) are now able to offer significant sustainable advantages and savings to lithium due to less impact from extraction and transportation. In addition, the anhydrous calcium-based thickener is stable and more Predictable. It is of biodegradable status and is abundant in supply, found in many continents and countries around the world. It also offers a low risk to handlers and manufacturers and is approved for food grade applications due to its low toxicity.

All these advantages are not the only success, the new anhydrous Calcium technology providing outstanding water resistance and surface adhesion, increased corrosion protection and shear stability. This product is ideal for many universal applications such as marine, agriculture, forestry, food grade and environmentally acceptable greases. Suited for the lubrication of plain bearings, wire ropes, chains, rails, and geared applications across a full range of equipment, where operating temperatures are not excessively high.

A WIDE RANGE OF GREASES FOR A WHOLE VARIETY OF USES:

Here at Witham Group, we have a wide range of reliable grease products, all designed for many different types of machinery, vehicles, equipment and uses. We supply greases to various sectors, including Agriculture, Plant & Off Road, Forestry, Marine, Automotive, Commercial Vehicles, Classic & Vintage and Horticulture.

Not Sure Which Grease To Use?

Witham Group would like to ensure you are using the correct grease for the correct application at all times, and once contacted we can send one of our team to your site to confirm this, offering alternatives if necessary. We will ensure that you are using the most suitable and cost-effective products for your vehicles and machinery and help rationalise the number of different products. The process is entirely free, so please get in touch today.

Leave a Reply