Oil in the beginning: ever wondered how oil is made?

Before we can make the lubricants and greases you know well, such as traditional engine oils and brake fluids, we need to start with base oil. Before we can get base oil, which comes from global oil refineries, we need to look at how the natural oil is formed and extracted.

This is the first in our technical series, that hopefully gives you an insight into the journey of oils and lubricants and some interesting facts that you may not know…

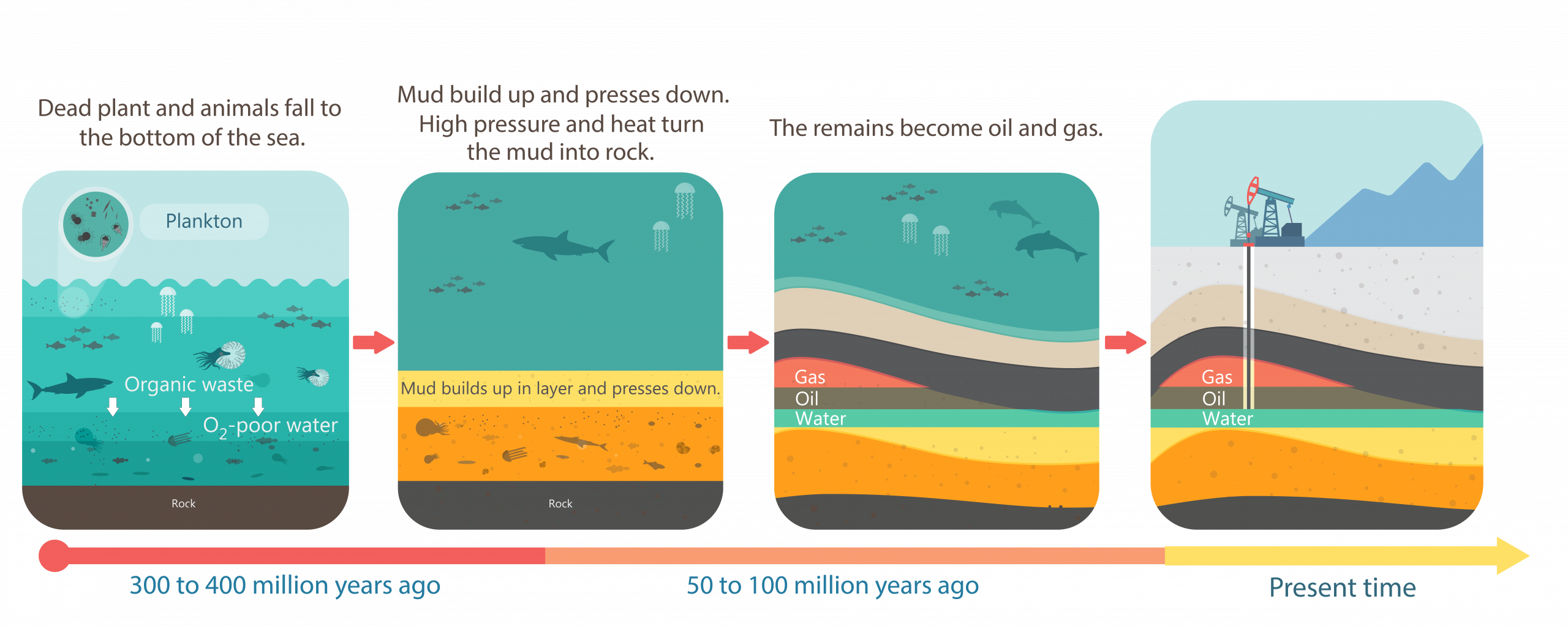

Crude oil is formed from tiny plants and animals called plankton which died in the oceans of the world and fell to the bottom of the sea, during the Jurassic Period, over 180 million years ago. Sediments like mud formed over the dead plankton and over time, the layers were subjected to heat and pressure, which turned the sediments to rock and the plankton to hydrocarbons formed in oil and gas. Dense rock from the sediments were sometimes created and were non-porous, trapping the oil and gas under a strong “Cap rock”. If a Cap Rock did not exist, then the oil and gas would seep to the surface either under the ocean or under dry land.

Oil Exploration

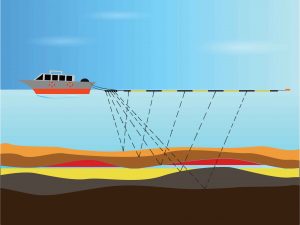

The presence of a cap rock formation is often what is searched for by oil explorations at sea and on land. It can be detected by a technique of controlled shock wave explosions and seismic mapping, which draws a picture and enables detailed analysis of where the likelihood of an oil bearing reservoir might be. Drilling down under the Cap Rock is the final proof to check its existence. Seismic Mapping comes in various guises. Compressed guns shoot pulses of air in the water, Thumper trucks slam heavy plates into the ground for exploration over land. Explosives are drilled into the ground or thrown overboard for sea exploration and then detonated.

Numerous sensitive listening devices pick up the sound waves reflected off boundaries of different layers of rock or refracted through rock layers which reveal where rocks, faults, oil, water and gas lie. Once seismic mapping has been established, the possibility of oil drilling and extraction is “weighed up” with costs of extraction, against supply, demand and pricing economics.

Extraction & Drilling

The dangerous job of drilling for oil requires a lot of equipment, time and is often fraught with problems. Drilling can take place on land or at sea and drilling machinery such as drill bits, blow out preventers, drill pipes, valves and collars are required on a very large scale for both on and off shore extraction.

The depth of an oil well can be thousands of feet, and pipes and drill bits can break a long way down resulting in the pipes needing to be withdrawn and replaced. Hard rock to drill through can require expensive diamond tipped bits and lubricating the drill bits can be challenging. The possibility of forming oil and or gas deposits depends on a combination of a number of favourable geological conditions. Oil and gas may have formed but then may have escaped because none of it was captured underneath a cap rock.

Crude Oil Varieties

Oil straight from the ground comes in various types and qualities depending on its geographical locations and other influences and ultimately refining techniques:

- Sweet or sour crude has a high Sulphur content

- Paraffinic or Naphthenic crude relates to the molecular structure within the oil formed by the different types of hydrocarbons – either rings or chains

- Light or heavy crude relates to the molecule size

- Shale oil is a type of heavy crude present in porous rock

Refining

Think of a refinery as a factory, which takes the raw material of crude oil and transforms it into petrol, base oil, lubricants and hundreds of other useful products. A typical large refinery costs billions of pounds to build and millions more to run and upgrade. It runs around the clock 365 days a year and employs hundreds of people across land that is as big as a hundred football pitches or more. A refinery breaks crude oil down into its various components which are then selectively changed into new products.

This process takes place inside a maze of pipes and vessels, which is operated from a highly automated control room. All refineries perform three main steps:

- Separation (fractional distillation)

- Coker (thermal cracking) to change value to say petrol and diesel

- Conversion – (reforming etc)

A Refinery Fractionating Column contains the crude oil and heat is applied to breakdown the long carbon chains of the hydrocarbons to shorter chains which move up the fractionating column chamber. A “Bubble Cap” lets the lighter gases rise but not return. At the top of the column the more lighter, highly flammable, paler gases and liquids are formed with short carbon chains. At the bottom, more heavy, thicker, darker and viscous liquids remain with heavier molecules, higher boiling points and low volatility. Petrol comes off near the top of the column. Cracking is the most widely used conversion method.

By applying heat to break down the long carbon chains to short chains the move up the fractional column to create different viscosities of products for different uses. Lubricant base oils – the main component and starting ingredients for engine oils, gear oils, brake fluids etc, are refined by taking the raw distillate streams and subjecting them to their own special processes to “clean them up”. Methods include; vacuuming, solvent washing, de-waxing, hydrocracking or polymerization all designed to improve the quality of the products. This is basically how mineral base oils are manufactured and we will then consider in the next edition of the Oily Rag how additives and other components are added to manufacture the different types of oils we know today. We will also consider the

role that lubricants play in keeping vehicles and machinery operating effectively for long periods avoiding costly breakdowns and wear and tear.

We have over 100 years of lubricant expertise. To read more about our technical knowledge and for help and advise, visit our website here.

Leave a Reply