Our Environmental Progress Continues

Despite the huge range of products that we manufacture and supply, our aim is always to operate within a climate of excellence, not only in terms of service and procedures for customers, but also for systems of product manufacture, the welfare, health and safety of all of our employees and those people affected by our activities.

The Environment and sustainability are extremely important to us, and we aim to operate with corporate care and social responsibility. In an industry where traditionally additives, chemicals and fossil-based products are essential to the manufacturing process, we have challenged ourselves to ensure, wherever possible, the environment is at the heart of our activities. We are working extremely hard to create a “greener culture” within our business.

At all levels, and within all functions of the Group, we are committed to continual improvement of our management systems and enhancement of our environmental performance. This policy, with its goals, aims and objectives, has been established to reflect our determination to ensure that wherever practically possible, our activities including purchasing, manufacturing, distribution, waste generation and disposal, will minimise the effect on the environment and prevent pollution. Reviewed at regular intervals and on the agenda at Board level and throughout the business, we strive to continually improve all areas of our activities and the impact we have on the environment. We will always comply with relevant environmental legislation and industry codes of practice as well as any other compliance obligations, as a minimum level of performance.

Last year we set out 4 main objectives for the business to achieve and work towards, to continue on our journey to improve as much as we can. Here we review how we got on in 2022…

Objective 1:

To eliminate paper as much as possible in all our internal processes using handheld digital devices, only sending one delivery note copy & more efficient label printing.

UPDATE:

So far, we have reduced our standard use of paper for general communications, invoices and statements and credit application forms by over 60%. We are continuing to contact customers who received printed versions of these documents to get up to date email addresses to transfer more over in the future. Implementation of our new ERP System will also eliminate hard paper copies as all products to be prepared will be displayed digitally.

Objective 2:

Further invest in energy auditing equipment once new offices are complete in an effort to move further towards a totally carbon neutral site.

UPDATE:

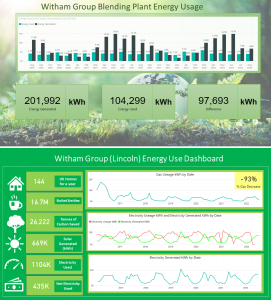

We are continually monitoring the use of our energy and the savings we are making with both our ultrasound blending processes and general carbon use in the factory. According to our energy dashboard which records our energy use, we have reduced the amount of gas usage by over 93%.

We are also working with the UEIL – Union of the European Lubricants Industry – to measure and account for, and reduce, the carbon footprint of their activities (corporate carbon footprint) and products (product carbon footprint).

We have a new Self-Assessment spreadsheet tool to complete with documents, measures and calculates the Carbon:

- Created by our own organisation

- Generated by energy consumption e.g., electricity

- Created by our suppliers, raw materials and other activities within the business such as travel, waste disposal etc.

We will be working towards being able to specifically measure each KG or CO2 produced compared to each KG of lubricant blended.

Objective 3:

To move our grease range to a non-Lithium based alternative to both free up this resource for electrification as well as reduce the overall carbon footprint of the grease production.

UPDATE:

We are launching for 2023, a new Calcium based Extreme Pressure Multi-Purpose Grease, that is made with Calcium and NOT Lithium. Lithium is a precious global resource, and the extraction process has quite a damaging effect on the landscape.

Qualube Extreme Pressure MP2 Grease is an anhydrous calcium thickened lubricating grease based on a mineral oil. Calcium is in much greater abundance as a resource across the globe and much less harmful extraction process. The grease contains antioxidants, corrosion inhibitors and EP/AW additives and the thickener, together with the special base oil blend, makes the product ideal for the lubrication of medium loaded bearings and in wet and corrosive environments.

The lubricating grease has excellent adhesion and water resistance. This is a high quality, multi-purpose grease that can be used in both industrial and automotive applications and is suitable for a wide range of plain and rolling bearings.

Objective 4

Promote the invention of carbon neutral blending process to the lubricant industry.

UPDATE:

Blendtek Solutions, which showcases our Ultrasound Blending innovation, has been highly visible this year. We have helped update their website and produce a presentation to the UKLA in London and UEIL in Athens at their sustainability conferences, promoting the benefits and savings of this ground-breaking innovation for the lubricant industry.

We have also submitted articles to LUBE Magazine and also helped promote to through Lubes & Greases Magazine, as well as it being part of our factory tour presentations to car clubs, agricultural groups, engineers and distributors.

Leave a Reply